Case Study – Streamlined Production

Case Study: Streamlining Production Through Simplified Supply Chain Solutions

A leading supplier of specialist roofing systems approached Milton Keynes Pressings (MKP) to help resolve significant inefficiencies in their production process. The customer’s existing supply chain had become overly complex, involving multiple suppliers, extended lead times, and inconsistent quality control. MKP was brought in to consolidate the process and deliver a more reliable, cost-effective manufacturing solution.

The Challenge

The customer’s original setup relied on a fabricated bracket, manufactured by several separate suppliers for laser cutting, forming, machining, and finishing operations.

While this multi-tiered approach initially provided flexibility, it soon led to major issues:

- Prolonged lead times due to logistics between suppliers

- Inconsistent part quality caused by varying production standards

- Increased administrative overhead managing multiple partners

- Limited visibility and control over the end-to-end process

The customer needed a single-source solution that could handle presswork, fabrication, and finishing under one roof — without compromising on quality or delivery performance.

The Solution

After a detailed process review, Milton Keynes Pressings proposed a fully integrated manufacturing solution. MKP absorbed the fragmented supply chain by taking on all stages of the production process — from tool design and pressing to forming and finishing.

Key actions included:

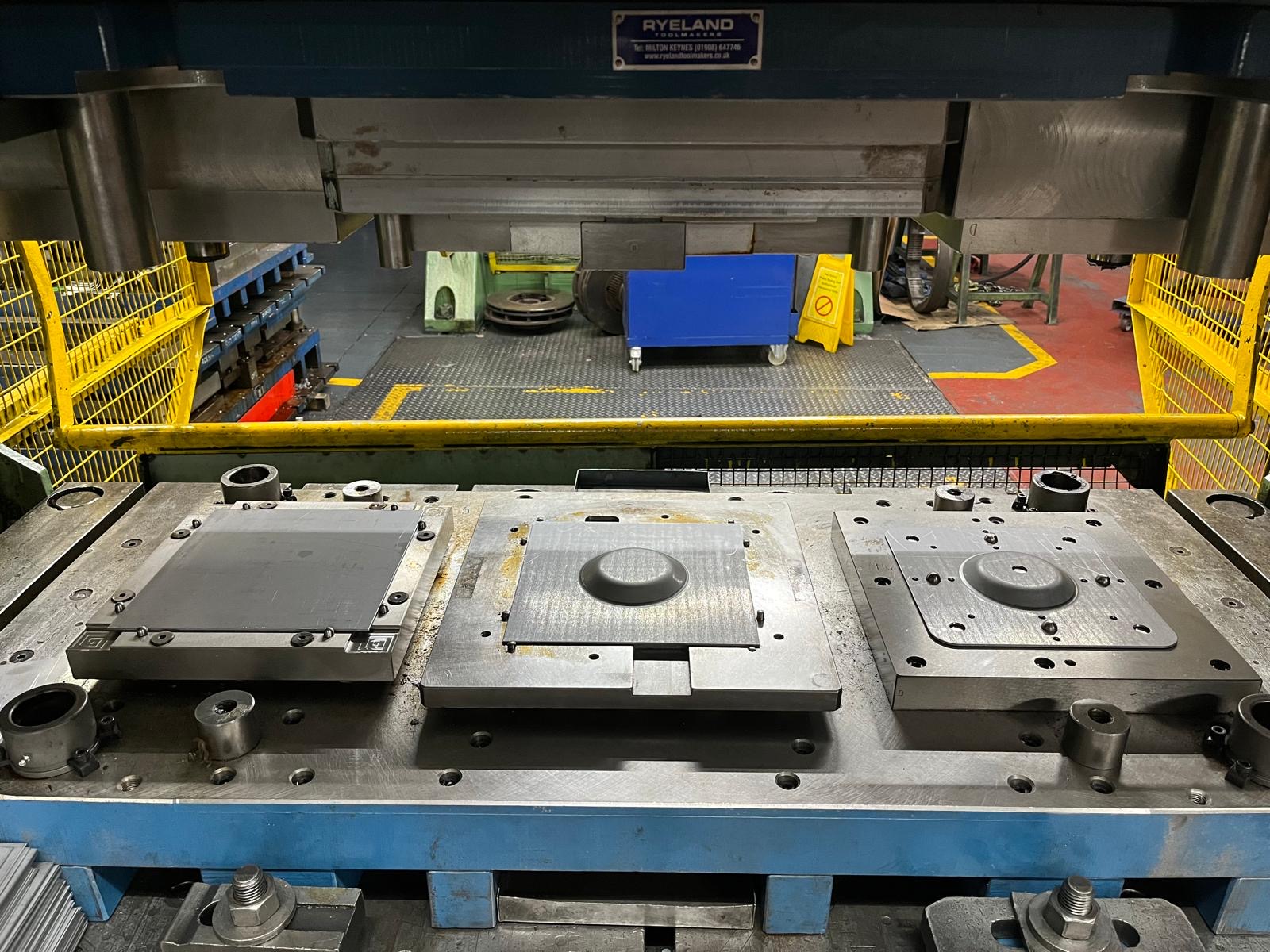

- Process modification and optimization: MKP’s in-house tooling engineers revalidated and offered a pressed alternative for better consistency and efficiency. With Ryeland Toolmakers within the MKP Group, all elements of design and manufacture were controlled and monitored

- In-house process integration: The introduction of a 3-Stage tool alleviated the need for separate laser and forming operations. MKP’s in-house Powder coat line offered the surface finish level required, ensuring that all processes were managed on-site to reduce logistics and handling costs.

- Enhanced supply chain management: MKP’s production planning MRP system offers schedules to align directly with the customer’s production line.

- Quality assurance: Full PPAP and IATF 16949-aligned quality controls were established to guarantee part conformity and traceability.

The Results

The transition to MKP’s consolidated approach delivered immediate measurable benefits;

| Outcome | Impact |

| Lead time reduction | faster delivery cycle |

| Cost savings | Approx. 75% total supply chain cost reduction |

| Quality improvements | 0 customer returns since transfer |

| Supply chain simplification | From 4 suppliers to 1 integrated partner |

The customer not only regained control of their production flow but also achieved greater reliability, reduced risk, and enhanced product quality — all while lowering total cost of ownership.

Customer Feedback

“Milton Keynes Pressings took the time to understand the root causes of our supply chain issues. By consolidating everything under one roof, and offering an improved manufacturing process, they’ve given us the control and efficiency we were missing. Their responsiveness and quality have exceeded our expectations.”

— Operations Director, Specialist Roofing System Manufacturer

Conclusion

By partnering with Milton Keynes Pressings, the customer transformed a complicated, multi-supplier process into a streamlined, high-performance operation. This case demonstrates MKP’s ability to simplify complex manufacturing challenges, provide end-to-end production solutions, and deliver reliable results across demanding industries.